Cleaning Labour Efficiency

The most effective, efficient and sustainable way to clean your food manufacturing factory.

Read the article

Foam vs Film - Why Films Are the Future of Food Hygiene

Traditional foam cleaners might look effective, but they deliver minimal chemical to the surface and come with high waste and effort. Discover how Foodclean’s film-based detergents provide superior coverage, longer dwell times, and easier rinsing. Watch our latest video and see the future of food hygiene in action.

The Food Safety Conference Return for 2025!

The Food Safety Innovation Conference is back for 2025—bringing together food industry professionals, hygiene experts, and manufacturers to share ideas, tackle challenges, and showcase the latest innovations in food safety and cleaning technology. Get a preview of what to expect and why this event is a must-attend for anyone in the sector.

Maximise Food Factory Efficiency with Labour-Saving Hygiene Solutions

Labour-saving cleaning equipment and systems can significantly improve hygiene performance and productivity across your factory. In this article, we explore how reducing manual effort, standardising cleaning methods, and investing in ergonomic, efficient tools can help your team clean better, faster, and more safely—supporting whole factory efficiency.

Whole Factory Efficiency: Minimising Chemical Waste in Local Cleaning Processes

Efficiency doesn’t stop at the production line—your hygiene systems play a vital role too. This article explores how FoodClean’s smarter, more sustainable cleaning solutions can help you achieve whole factory efficiency, from reduced water and chemical usage to faster changeovers and improved safety.

What is cross-contamination and how to prevent it?

Cross-contamination is one of the biggest threats to food safety in manufacturing environments. From equipment handling to zone separation and effective cleaning processes, this article outlines the key steps your hygiene team can take to minimise risk and stay compliant with industry standards.

The Essential Role of Caustic Detergents in Food Production Cleaning

Caustic detergents are powerful cleaning agents used across the food industry to break down fats, oils, and protein deposits. In this article, we explore why they’re crucial for effective cleaning in food production environments, how they work, and the safety considerations every hygiene team should know.

The Importance of Acidic Cleaning Products in Managing Water Hardness in Food Factories

Acidic cleaning products are essential in food manufacturing for removing mineral deposits, scale, and stubborn residues that alkaline detergents can’t break down. This article explains when to use acidic cleaners, how they support hygiene compliance, and the safety considerations your team should follow for effective and responsible use.

Achieve Whole Factory Efficiency with Foodclean’s Total Cost of Clean (TCC™) Methodology

True factory efficiency goes beyond the production line—your hygiene systems play a vital role too. FoodClean’s intelligent solutions are designed to optimise every stage of the cleaning process, from reducing changeover times and chemical usage to improving staff safety and workflow. Learn how to unlock whole factory performance through smarter, more sustainable hygiene strategies.

Storing Chemicals in Winter

When temperatures drop, cleaning chemicals can become unstable, less effective, or even hazardous. This guide explains how to safely store your hygiene chemicals through the winter—protecting product performance, maintaining compliance, and keeping your team safe in colder conditions.

Food Safety Innovation Conference 2023

FoodClean and Klipspringer present the Food Safety Innovation Conference on Sept 5, 2023, at the University of Lincoln. This event features expert-led workshops, presentations, and discussions to enhance food industry standards.

Why Switch to Medium Pressure Cleaning in Food Manufacturing?

Discover why more food manufacturing facilities are switching from high pressure to medium pressure cleaning systems. This guide explains the safety, efficiency, and cost-saving benefits of medium pressure, including reduced water usage, less risk of damage to surfaces and machinery, and improved cleaning outcomes. Learn how upgrading your hygiene systems can boost productivity while protecting your people and your plant.

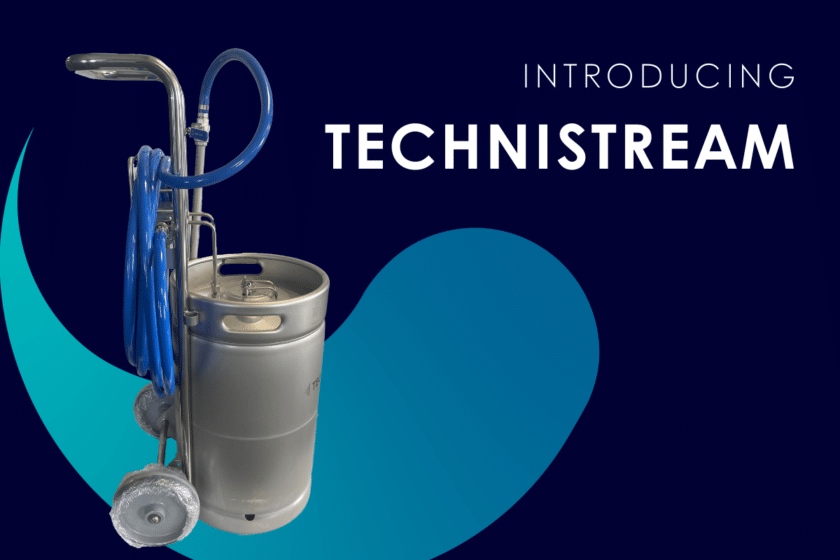

Technistream Foamer Saves Time, Labour, Water and Money

The Technistream 50L and 20L foamers use compressed air to apply dense, dry foam for effective cleaning in food manufacturing and other industries. With no moving parts, they offer a low-maintenance, efficient solution for chemical application.